S series W series D series Clean Piggy Rakuraku Robo Eco Seeder Products

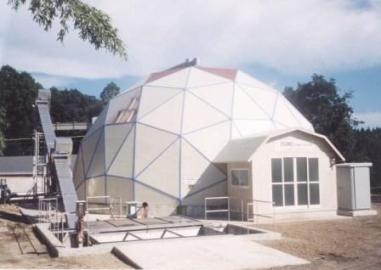

Dome Compo System

|

Benefits |

|---|---|

|

It is an environment friendly circulation recycling system.

Waste incineration facilities in urban areas are starting to reach the limit. Further, we are living in an environment in which the problem of dioxin emissions, etc. can no longer be ignored.

Based on years of accumulated experience in composting technology, our company has has developed a fully airtight composting plant in consideration of our regional environment and with the goal of co-existing with society.

This system turns organic waste, into fully matured compost by decomposing and deodorizing with active microbe.

We believe this also has great significance from the standpoint of recycling our resources.

| Specification | ||||

|---|---|---|---|---|

| Main unit | Motor | |||

| Fermenter volume | 325m³ | Hydraulic pump (for agitation, outside use) |

15.0kw | |

| Fermenter inside diameter | 13.5m | Hydraulic pump (for agitation, inside use) |

15.0kw | |

| Fermenter depth | 2.3m | Hydraulic pump (for agitation, spare) |

15.0kw | |

| Fermenter weight | 23ton | Hydraulic pump (for rotation) |

3.7kw | |

| Agitator weight | 19ton | Hydraulic pump (loading case conveyor) (No.2,3,4) |

7.5kw | |

| Dome building diameter | 16m | Screw conveyor for loading hopper | 2.2kw | |

| Dome building height | 8.8m | Loading case conveyor (No.1) | 4.4kw | |

| Dome building thickness | 200mm | Fermentation blower (5.5kwX4) | 22.0kw | |

| 200mm | Fermentation pressurized fan | 0.4kw | ||

| Material removal conveyor | 3.0kw | |||

| Lubrication pump (0.04kwX2) | 0.08kw | |||

| Odor exhaust blower | 7.5kw | |||

| Total | 95.8kw | |||

| Processing capacity by industry | ||||

| Item | Moisture content | Processing amount (/day) | Farm scale | |

| Raw waste | 85% | 25m³ | 20ton | - |

| Pig manure | 78% | 25m³ | 20ton | 1,500 mother pigs |

| Poultry manure | 68% | 35m³ | 28ton | 350,000 chickens |

| Milk cattle, beef cattle | Will be designed according to the raising style. | - | ||